Lined fluorine globe valve

Lined fluorine globe valve

Nominal diameter: DN15 ~ 350mm

Pressure rating : 0.6,1.0,1.6 MPa

Suitable temperature: ≤80 ℃, ≤100 ℃, ≤120 ℃, ≤150 ℃, (according to lining material)

Design and manufacture: GB12235

Structure length: GB12221 (1 series)

Flange connection size: GB4216

product description

J41F46 lined with fluorine plastic stop valve for a variety of concentrations of -50 ~ 150 ℃ aqua regia, acid, hydrochloric acid, hydrofluoric acid and a variety of organic acids, acids, strong oxidants, but also for a variety of concentrations of strong alkali organic Solvents and other corrosive gases, liquid media used on the pipeline.

Product Usage

J41F4 lined with fluorine plastic globe valve is designed to control strong corrosive medium, the body cavity surface covered with a variety of fluoroplastic options for different operating temperatures and fluid lines. High strength, good corrosion resistance.

Valve test

Lining: EDM testing

and testing according to GB / T13927 standard

Nominal pressure: PN Body: PN × 1.5 Seal: PN × 1.1

Main material

Body: cast iron, carbon steel Stainless steel bonnet: cast iron, carbon steel stainless steel Lining: Fluoroplastic

flap: carbon steel, stainless steel, completely coated Fluoroplastic stem: carbon steel, stainless steel, partially coated fluoroplastic Handwheel: cast iron , Carbon steel

Parts list

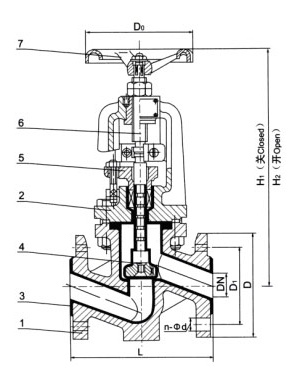

1, valve body, 2, valve cover 3, valve body 4, valve flap 5, pressure cover 6, valve stem 7, handle

DN | PN | Work pressure | L | D | D1 | n-Фd | H1 | H2 | D0 | quality |

15 | 1.6 1.0 | 1.6 | 130 | 95 | 65 | 4-14 | 225 | 240 | 100 | 4 |

20 | 150 | 105 | 75 | 4-14 | 230 | 250 | 100 | 6 | ||

25 | 160 | 115 | 85 | 4-14 | 264 | 288 | 120 | 8 | ||

32 | 180 | 140 | 100 | 4-18 | 272 | 296 | 120 | 10.5 | ||

40 | 200 | 150 | 110 | 4-18 | 300 | 325 | 140 | 16.5 | ||

50 | 230 | 165 | 125 | 4-18 | 321 | 346 | 140 | 18 | ||

65 | 290 | 185 | 145 | 4-18 | 366 | 396 | 160 | 26 | ||

80 | 310 | 200 | 160 | 6 / 2-18 | 400 | 438 | 200 | 36.5 | ||

100 | 350 | 220 | 180 | 6 / 2-18 | 476 | 517 | 280 | 58 | ||

125 | 1.0 | 400 | 250 | 210 | 6 / 2-18 | 530 | 560 | 280 | 64 | |

150 | 480 | 285 | 240 | 6 / 2-22 | 650 | 605 | 320 | 85 | ||

200 | 495 | 340 | 295 | 6 / 2-22 | 650 | 770 | 360 | 155 | ||

250 | 0.6 | 622 | 395 | 350 | 8 / 4-22 | 690 | 810 | 400 | 243 | |

300 | 698 | 445 | 400 | 8 / 4-22 | 730 | 845 | 400 | 295 | ||

350 | 787 | 505 | 460 | 12 / 4-22 |